| Availability: | |

|---|---|

| Quantity: | |

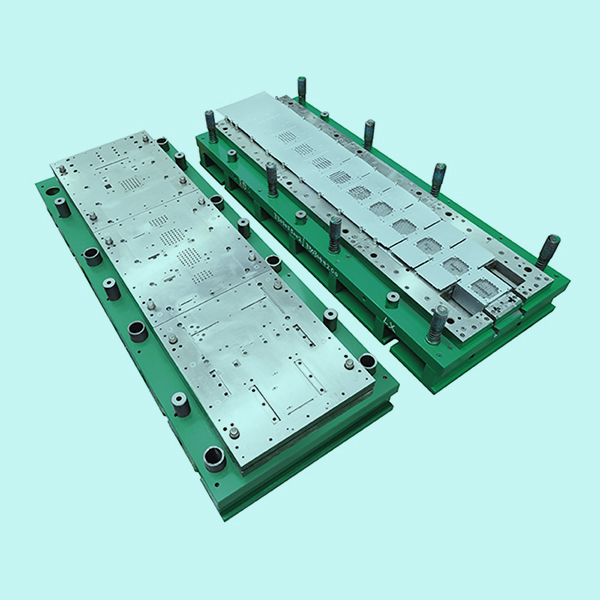

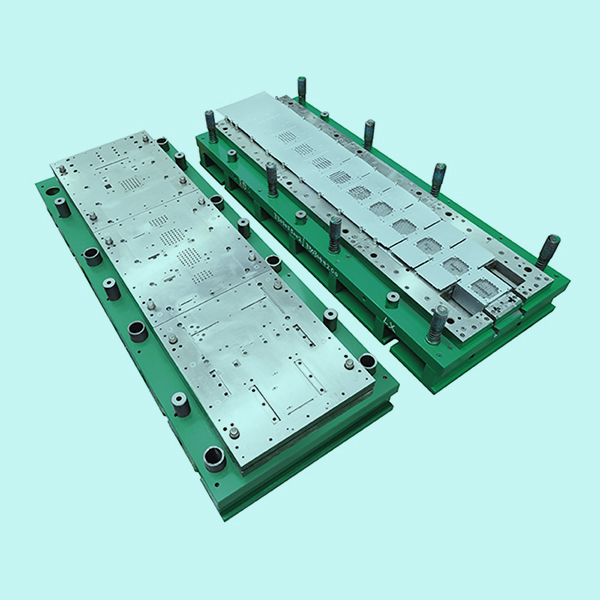

Machine industry

Mould

Auto parts

Siemens 828D system | Imported 20000rpm electric spindle |

Spindle automatic constant temperature cooling circulation system | Automatic grease lubrication system or coordinate axes |

Machine pneumatic system | Spindle taper air seal |

Automatic chip converyor on both sides of the worktable | Cutting tool cooling system and large capacity water tank |

| Semi-closed cover | Door open switch |

MPG | Tricolor working light |

Electric cabinet air conditioner | Standard accessories and documents |

| Chain type chip conveyor. |

| Fanuc system | Three axis full closed loop control |

| Cooltant throught spindle | Workpiece micro cooling system, |

Description | Unit | HGM2030/HGM2030AC |

Processing range | ||

Gantry effective width | mm | 2050 |

X Travel | mm | 3000 |

Y Travel | mm | 2000 |

Z Travel | mm | 700 |

Distance from the vertical end face of the spindle to the working table | mm | 50-750 |

Distance from the horizontal center of the spindle to the working table | mm | 312-1012 |

Table | ||

Table size(W*L) | mm | 2000*3000 |

Max loading | T | 6T |

Column width | mm | 2050 |

Table T-slot | r/min | 12-18*250 |

A/C head | ||

C axis rotation range | ° | ±180° |

A axis rotation range | ° | ±90° |

Vertical head spindle speed range | Rpm | 10-24000 |

spindle torque | N.m | 19/21 |

Spindle taper | HSK-A63 | |

Feed | ||

Range of cutting feed speed | m/min | 10-20 |

X axis rapid speed | m/min | 30 |

Y axis rapid speed | m/min | 40 |

Z axis rapid speed | m/min | 36 |

Accuracy | ||

X-axis positioning accuracy (semi-closed loop) | mm | 0.045 |

Y axis positioning accuracy (semi-closed loop) | mm | 0.035 |

Z axis positioning accuracy (semi-closed loop) | mm | 0.025 |

X-axis repeated positioning accuracy (semi-closed loop) | mm | 0.025 |

Y-axis repeated positioning accuracy (semi-closed loop) | mm | 0.02 |

Z-axis repeated positioning accuracy (semi-closed loop) | mm | 0.015 |

Numercial control system | SIEMENS | |

Others | ||

Machine size(L*W*H) | mm | 7000*4600*4000 |

Machine weight | T | 25 |

Gantry frame adopts four bilateral servo motors,electronic backlash elimmination and synchronous drive to ensure stable and reliable operation of column sliding.

Machine body with worktable integral structure,column beam(integral),transverse slide plate,vertical slide plate are made of high strength and high quality ball mill cast iron material,strong rigidity,good shock absorption.

Adopt imported high speed spindle,the highest speed is 20000rpm,built in cooling device,the accuracy is durable adn reliable.Optional AC swing angle milling head to acheive fixed axis machining of axis A and C.

HSK clamping cutter,high precision ,static and dynamic rigidity and can safely and efficiently transfer torque.

Three axis with higher rapid speed,can make more significant efficiency.

Machine industry

Mould

Auto parts

Siemens 828D system | Imported 20000rpm electric spindle |

Spindle automatic constant temperature cooling circulation system | Automatic grease lubrication system or coordinate axes |

Machine pneumatic system | Spindle taper air seal |

Automatic chip converyor on both sides of the worktable | Cutting tool cooling system and large capacity water tank |

| Semi-closed cover | Door open switch |

MPG | Tricolor working light |

Electric cabinet air conditioner | Standard accessories and documents |

| Chain type chip conveyor. |

| Fanuc system | Three axis full closed loop control |

| Cooltant throught spindle | Workpiece micro cooling system, |

Description | Unit | HGM2030/HGM2030AC |

Processing range | ||

Gantry effective width | mm | 2050 |

X Travel | mm | 3000 |

Y Travel | mm | 2000 |

Z Travel | mm | 700 |

Distance from the vertical end face of the spindle to the working table | mm | 50-750 |

Distance from the horizontal center of the spindle to the working table | mm | 312-1012 |

Table | ||

Table size(W*L) | mm | 2000*3000 |

Max loading | T | 6T |

Column width | mm | 2050 |

Table T-slot | r/min | 12-18*250 |

A/C head | ||

C axis rotation range | ° | ±180° |

A axis rotation range | ° | ±90° |

Vertical head spindle speed range | Rpm | 10-24000 |

spindle torque | N.m | 19/21 |

Spindle taper | HSK-A63 | |

Feed | ||

Range of cutting feed speed | m/min | 10-20 |

X axis rapid speed | m/min | 30 |

Y axis rapid speed | m/min | 40 |

Z axis rapid speed | m/min | 36 |

Accuracy | ||

X-axis positioning accuracy (semi-closed loop) | mm | 0.045 |

Y axis positioning accuracy (semi-closed loop) | mm | 0.035 |

Z axis positioning accuracy (semi-closed loop) | mm | 0.025 |

X-axis repeated positioning accuracy (semi-closed loop) | mm | 0.025 |

Y-axis repeated positioning accuracy (semi-closed loop) | mm | 0.02 |

Z-axis repeated positioning accuracy (semi-closed loop) | mm | 0.015 |

Numercial control system | SIEMENS | |

Others | ||

Machine size(L*W*H) | mm | 7000*4600*4000 |

Machine weight | T | 25 |

Gantry frame adopts four bilateral servo motors,electronic backlash elimmination and synchronous drive to ensure stable and reliable operation of column sliding.

Machine body with worktable integral structure,column beam(integral),transverse slide plate,vertical slide plate are made of high strength and high quality ball mill cast iron material,strong rigidity,good shock absorption.

Adopt imported high speed spindle,the highest speed is 20000rpm,built in cooling device,the accuracy is durable adn reliable.Optional AC swing angle milling head to acheive fixed axis machining of axis A and C.

HSK clamping cutter,high precision ,static and dynamic rigidity and can safely and efficiently transfer torque.

Three axis with higher rapid speed,can make more significant efficiency.