Auto parts

Machine manufacturer

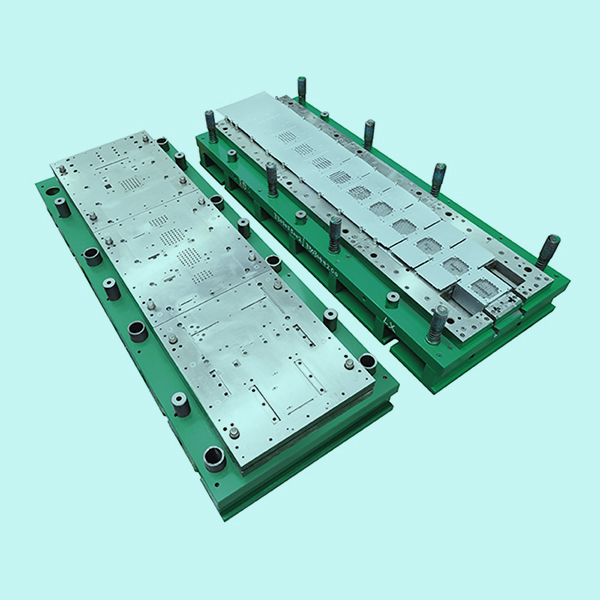

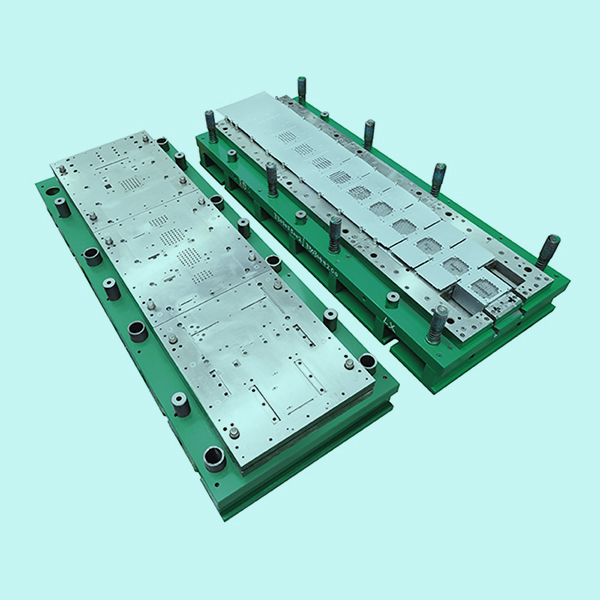

Mould

| Cooltant system | hydraulic station | lubrication system | working light | leveling wedges |

| foundation screw | wheel flange | wheel balance arbor | tool and tool box | magnetic chuck |

| standard wheel | PLC controller | operation manual | touched screen |

dust collection device | paper filter | magetic separator | wheel balance stand | Y Z axis DRO |

Description | Unit | MG2050NC2 |

Table size(L*W) | mm | 210*480 |

Max stroke(W*L) | mm | 260*580 |

T-slot of table(No.*width) | mm | 1*14 |

Distance from spindle center to worktable | mm | 420 |

Max. loading of table(including magentic chuck) | kg | 120 |

Magnetic chuck size | mm | 460*200 |

Wheel size(OD*Width*ID) | mm | 200*13* 31.75 |

Spindle speed(stepless) | r/min | 0-3600 |

Worktable speed | m/min | 3-25 |

Vertical feed MPG (pulse feed) | mm | 0.0001/0.001/0.01 |

Vertical feed MPG (inching feed) | mm | 0.0001 |

Vertical auto feed | mm/stoke | 0.0005-0.05 |

Sparkless grinding times | time | 0-10 |

Rapid feed speed | Mm/min | 500 |

Transverse feed MPG(pulse feed) | mm | 0.0005/0.005/0.05 |

Transverse feed MPG(inching feed) | mm | 0.0005 |

Transverse rapid feed | mm/min | 50-1000 |

Spindle motor | KW | 2.2 |

Hydraulic motor | KW | 2.2 |

Cooltant motor | KW | 0.125 |

Elevating servo motor | KW | 3 |

Transverse feed motor | KW | 8.5 |

Total rated power | KW | 6 |

Surface roughness | μm | Ra0.16 |

Parallesim fo machined surface to datum plane | mm | 300:0.003 |

Gross weight | kg | 2800 |

Description | Unit | MG40100NC2 |

Table size(L*W) | mm | 406*1020 |

Max stroke(W*L) | mm | 460*1130 |

T-slot of table(No.*width) | mm | 3*14 |

Distance from spindle center to worktable | mm | 560 |

Max. loading of table(including magentic chuck) | kg | 500 |

Magnetic chuck size | mm | 400*1000 |

Wheel size(OD*Width*ID) | mm | 400*40*127 |

Spindle speed(stepless) | r/min | 100-3600 |

Worktable speed | m/min | 5-25 |

Vertical feed MPG (pulse feed) | mm | 0.001/0.01 |

Vertical feed MPG (inching feed) | mm | 0.001 |

Vertical auto feed | mm/stoke | 0.001-0.05 |

Sparkless grinding times | time | 0-10 |

Rapid feed speed | Mm/min | 500 |

Transverse feed MPG(pulse feed) | mm | 0.001/0.01 |

Transverse feed MPG(inching feed) | mm | 0.001 |

Transverse rapid feed | mm/min | 1-1000 |

Spindle motor | KW | 5.5 |

Hydraulic motor | KW | 0.75 |

Cooltant motor | KW | 0.125 |

Elevating servo motor | KW | 2.4 |

Transverse feed motor | KW | 2.4 |

Total rated power | KW | 6 |

Surface roughness | μm | Ra0.16 |

Parallesim fo machined surface to datum plane | mm | 300:0.003 |

Gross weight | kg | 4500 |

It adopts the layout of cross drag plate, and the main components adopt the new symmetrical structure design, which avoids the influence of temperature difference on the accuracy and has the rigidity of high strength structure and good damping performance.

The precision of the machine can reach um (0.001mm) level.

The table along the saddle left and right moving guideway for double V guideway, guide rail surface using manual, precision scraping development, left and right moving by independent hydraulic station closed hydraulic system drive, with strong rigidity, small thermal deformation, high grinding accuracy.

Preloaded precise linear guideway and precise ball screw drive are used for the lower and front and back movement of the grinding head, which can do accurate feeding with high repeatability.

The spindle for the special grinding head spindle, using dynamic pressure technology, sleeve structure into the spindle, spindle motor with elastic coupling and direct connection with spindle.

Dedicated man-machine interface for grinding, making grinding more simple and efficient.

Auto parts

Machine manufacturer

Mould

| Cooltant system | hydraulic station | lubrication system | working light | leveling wedges |

| foundation screw | wheel flange | wheel balance arbor | tool and tool box | magnetic chuck |

| standard wheel | PLC controller | operation manual | touched screen |

dust collection device | paper filter | magetic separator | wheel balance stand | Y Z axis DRO |

Description | Unit | MG2050NC2 |

Table size(L*W) | mm | 210*480 |

Max stroke(W*L) | mm | 260*580 |

T-slot of table(No.*width) | mm | 1*14 |

Distance from spindle center to worktable | mm | 420 |

Max. loading of table(including magentic chuck) | kg | 120 |

Magnetic chuck size | mm | 460*200 |

Wheel size(OD*Width*ID) | mm | 200*13* 31.75 |

Spindle speed(stepless) | r/min | 0-3600 |

Worktable speed | m/min | 3-25 |

Vertical feed MPG (pulse feed) | mm | 0.0001/0.001/0.01 |

Vertical feed MPG (inching feed) | mm | 0.0001 |

Vertical auto feed | mm/stoke | 0.0005-0.05 |

Sparkless grinding times | time | 0-10 |

Rapid feed speed | Mm/min | 500 |

Transverse feed MPG(pulse feed) | mm | 0.0005/0.005/0.05 |

Transverse feed MPG(inching feed) | mm | 0.0005 |

Transverse rapid feed | mm/min | 50-1000 |

Spindle motor | KW | 2.2 |

Hydraulic motor | KW | 2.2 |

Cooltant motor | KW | 0.125 |

Elevating servo motor | KW | 3 |

Transverse feed motor | KW | 8.5 |

Total rated power | KW | 6 |

Surface roughness | μm | Ra0.16 |

Parallesim fo machined surface to datum plane | mm | 300:0.003 |

Gross weight | kg | 2800 |

Description | Unit | MG40100NC2 |

Table size(L*W) | mm | 406*1020 |

Max stroke(W*L) | mm | 460*1130 |

T-slot of table(No.*width) | mm | 3*14 |

Distance from spindle center to worktable | mm | 560 |

Max. loading of table(including magentic chuck) | kg | 500 |

Magnetic chuck size | mm | 400*1000 |

Wheel size(OD*Width*ID) | mm | 400*40*127 |

Spindle speed(stepless) | r/min | 100-3600 |

Worktable speed | m/min | 5-25 |

Vertical feed MPG (pulse feed) | mm | 0.001/0.01 |

Vertical feed MPG (inching feed) | mm | 0.001 |

Vertical auto feed | mm/stoke | 0.001-0.05 |

Sparkless grinding times | time | 0-10 |

Rapid feed speed | Mm/min | 500 |

Transverse feed MPG(pulse feed) | mm | 0.001/0.01 |

Transverse feed MPG(inching feed) | mm | 0.001 |

Transverse rapid feed | mm/min | 1-1000 |

Spindle motor | KW | 5.5 |

Hydraulic motor | KW | 0.75 |

Cooltant motor | KW | 0.125 |

Elevating servo motor | KW | 2.4 |

Transverse feed motor | KW | 2.4 |

Total rated power | KW | 6 |

Surface roughness | μm | Ra0.16 |

Parallesim fo machined surface to datum plane | mm | 300:0.003 |

Gross weight | kg | 4500 |

It adopts the layout of cross drag plate, and the main components adopt the new symmetrical structure design, which avoids the influence of temperature difference on the accuracy and has the rigidity of high strength structure and good damping performance.

The precision of the machine can reach um (0.001mm) level.

The table along the saddle left and right moving guideway for double V guideway, guide rail surface using manual, precision scraping development, left and right moving by independent hydraulic station closed hydraulic system drive, with strong rigidity, small thermal deformation, high grinding accuracy.

Preloaded precise linear guideway and precise ball screw drive are used for the lower and front and back movement of the grinding head, which can do accurate feeding with high repeatability.

The spindle for the special grinding head spindle, using dynamic pressure technology, sleeve structure into the spindle, spindle motor with elastic coupling and direct connection with spindle.

Dedicated man-machine interface for grinding, making grinding more simple and efficient.