Auto Parts

Machine manufacturer

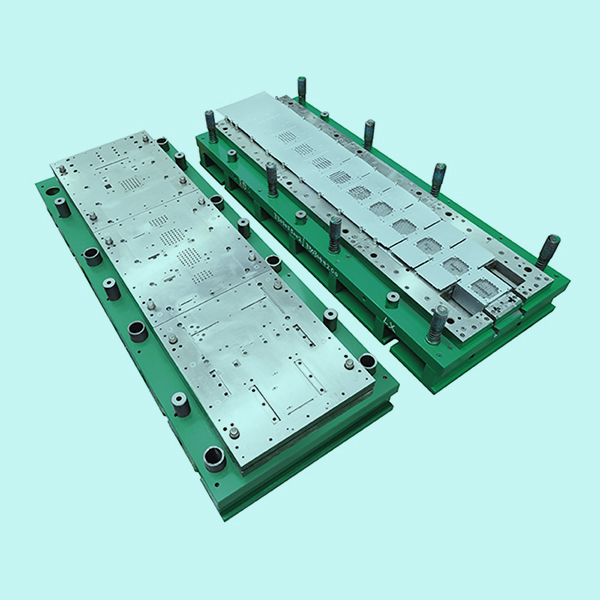

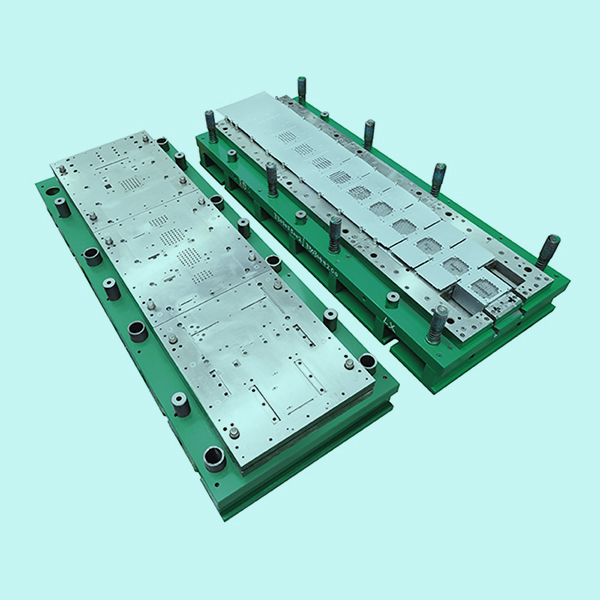

Mould

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

| PLC controller | touched screen |

diamond pen | magetic separator | wheel balance stand | DRO | dust collection |

Description | Unit | MG50100NC2 | |

Table size(L*W) | mm | 500*1200 | |

Max.grinding size of workpiece(L*W) | mm | 500*1000*420 | |

Distance from spindle center to table surface | mm | 600 | |

Magnetic chuck size | mm | 500*1000 | |

Table longitudinal speed | mm | 5-25 | |

Max. loading of table(including magentic chuck) | kg | 700 | |

Wheelhead Transverse moving | Rapid speed feed | m/min | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.002 | |

Wheel vertical moving | Rapid speed feed | m/min. | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.001 | |

Wheel size(OD*Width*ID) | mm | 355*50*127 | |

Surface roughness | μm | Ra0.16 | |

Gross weight | kg | 7500 | |

Package dimension(L*W*H) | cm | 450*220*172 260*227*255 | |

Description | Unit | MG60220PC2 | |

Table size(L*W) | mm | 2200*610 | |

Max.grinding size of workpiece(L*W) | mm | 2200*610 | |

Distance from spindle center to table surface | mm | 820 | |

Magnetic chuck size | mm | 600*1000*2 | |

Table longitudinal speed | mm | 5-25 | |

Max. loading of table(including magentic chuck) | kg | 1230 | |

Wheelhead Transverse moving | Rapid speed feed | m/min | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.002 | |

Wheel vertical moving | Rapid speed feed | m/min. | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.001 | |

Wheel size(OD*Width*ID) | mm | 500*75*305 | |

Total rated power | KW | 32 | |

Surface roughness | μm | Ra0.63 | |

Gross weight | kg | 12500 | |

Package dimension(L*W*H) | cm | 600*220*172 260*227*255 | |

Column mobile surface grinder is a collection of high-tech electromechanical and hydraulic integrated products. The machine adopts T-shaped layout, the grinding head body moves up and down along the column guide rail (Y-axis), the column moves forward and backward along the rear guide rail of the bed (Z-axis), and the table moves left and right along the guide rail of the bed (X-axis).

The bed is made of mineral materials to achieve good dynamic operation in the process of processing and ensure the flatness of the workpiece.

Grinding head for a box body structure, main shaft of dynamic and static pressure for high precision grinding head spindle, sleeve structure loading, spindle motor spindle direct connects with elastic coupling, the guide adopts precision linear guide rail, the up and down movement adopts servo motor through the cog belt wheel deceleration, drive the vertical rolling screw rotation and make it up and down. The grinding body moves more smoothly by balancing the hammer system.

The column is a frame-shaped box with double wall structure, which makes its structural rigidity stronger and more powerful. The bottom adopts linear guide rail, and the Z-direction movement is slowed down by the servo motor through the toothed belt wheel, which drives the rolling lead screw in the front and back directions to rotate and make it move forward and backward.

The worktable adopts the flat-V guide rail and sticks the teflon wear-resistant belt, moves around along the guide rail of the bed, adopts the double cylinder drive hydraulic drive, the double cylinder is fixed with the bed body; The hydraulic system adopts an independent hydraulic station outside the machine tool, and the oil cooling system is used to cool the hydraulic oil, so that the temperature rise of the oil temperature is reduced and the volume of the oil tank is reduced. Because there is no hydraulic oil inside the bed, the problem that the traditional grinder relies on the bed to cool the hydraulic oil and the grinding accuracy is affected by the oil temperature is unstable is solved. Its left and right direction is transmitted by proximity switch, special electro-hydraulic valve, stable and reliable. The movement speed of the worktable is stepless speed regulation by manual speed regulating valve, which is installed in the front of the bed.

The electrical control adopts PLC programmable controller to control each action, which makes the electric control system stable and reliable.

The Y and Z axes are driven by servo motor, and the electronic hand wheel is used for remote control to replace the traditional mechanical hand wheel. The transmission system is simplified, which makes the operation of the machine tool more humanized and the maintenance is simplified.

The button station adopts the console with rotating arm. The operation can be controlled on the panel except for the speed adjusting handle of the table in the front of the bed. The electric box adopts independent electric cabinet with air conditioning refrigeration.

The transverse distance can be directly set arbitrarily by the electric button on the panel. The setting is simple and more efficient. The feed amount can be set directly on the panel.

The machine is equipped with automatic size grinding function, can be fully automatic surface grinding to reach the set size and zero grinding (light knife), the grinding wheel can rise to the fixed point, so as to facilitate the loading and unloading of crops; The power supply of hydraulic motor is automatically turned off immediately, which makes grinding more automatic and greatly reduces labor cost.

The machine has automatic fault alarm function, if the lubricating oil level of the guide rail is too low or the pressure is too low, the machine can automatically stop and alarm.

Auto Parts

Machine manufacturer

Mould

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

| PLC controller | touched screen |

diamond pen | magetic separator | wheel balance stand | DRO | dust collection |

Description | Unit | MG50100NC2 | |

Table size(L*W) | mm | 500*1200 | |

Max.grinding size of workpiece(L*W) | mm | 500*1000*420 | |

Distance from spindle center to table surface | mm | 600 | |

Magnetic chuck size | mm | 500*1000 | |

Table longitudinal speed | mm | 5-25 | |

Max. loading of table(including magentic chuck) | kg | 700 | |

Wheelhead Transverse moving | Rapid speed feed | m/min | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.002 | |

Wheel vertical moving | Rapid speed feed | m/min. | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.001 | |

Wheel size(OD*Width*ID) | mm | 355*50*127 | |

Surface roughness | μm | Ra0.16 | |

Gross weight | kg | 7500 | |

Package dimension(L*W*H) | cm | 450*220*172 260*227*255 | |

Description | Unit | MG60220PC2 | |

Table size(L*W) | mm | 2200*610 | |

Max.grinding size of workpiece(L*W) | mm | 2200*610 | |

Distance from spindle center to table surface | mm | 820 | |

Magnetic chuck size | mm | 600*1000*2 | |

Table longitudinal speed | mm | 5-25 | |

Max. loading of table(including magentic chuck) | kg | 1230 | |

Wheelhead Transverse moving | Rapid speed feed | m/min | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.002 | |

Wheel vertical moving | Rapid speed feed | m/min. | 0.03-2 |

Handwheel feed per gra. | mm/gra. | 0.001 | |

Wheel size(OD*Width*ID) | mm | 500*75*305 | |

Total rated power | KW | 32 | |

Surface roughness | μm | Ra0.63 | |

Gross weight | kg | 12500 | |

Package dimension(L*W*H) | cm | 600*220*172 260*227*255 | |

Column mobile surface grinder is a collection of high-tech electromechanical and hydraulic integrated products. The machine adopts T-shaped layout, the grinding head body moves up and down along the column guide rail (Y-axis), the column moves forward and backward along the rear guide rail of the bed (Z-axis), and the table moves left and right along the guide rail of the bed (X-axis).

The bed is made of mineral materials to achieve good dynamic operation in the process of processing and ensure the flatness of the workpiece.

Grinding head for a box body structure, main shaft of dynamic and static pressure for high precision grinding head spindle, sleeve structure loading, spindle motor spindle direct connects with elastic coupling, the guide adopts precision linear guide rail, the up and down movement adopts servo motor through the cog belt wheel deceleration, drive the vertical rolling screw rotation and make it up and down. The grinding body moves more smoothly by balancing the hammer system.

The column is a frame-shaped box with double wall structure, which makes its structural rigidity stronger and more powerful. The bottom adopts linear guide rail, and the Z-direction movement is slowed down by the servo motor through the toothed belt wheel, which drives the rolling lead screw in the front and back directions to rotate and make it move forward and backward.

The worktable adopts the flat-V guide rail and sticks the teflon wear-resistant belt, moves around along the guide rail of the bed, adopts the double cylinder drive hydraulic drive, the double cylinder is fixed with the bed body; The hydraulic system adopts an independent hydraulic station outside the machine tool, and the oil cooling system is used to cool the hydraulic oil, so that the temperature rise of the oil temperature is reduced and the volume of the oil tank is reduced. Because there is no hydraulic oil inside the bed, the problem that the traditional grinder relies on the bed to cool the hydraulic oil and the grinding accuracy is affected by the oil temperature is unstable is solved. Its left and right direction is transmitted by proximity switch, special electro-hydraulic valve, stable and reliable. The movement speed of the worktable is stepless speed regulation by manual speed regulating valve, which is installed in the front of the bed.

The electrical control adopts PLC programmable controller to control each action, which makes the electric control system stable and reliable.

The Y and Z axes are driven by servo motor, and the electronic hand wheel is used for remote control to replace the traditional mechanical hand wheel. The transmission system is simplified, which makes the operation of the machine tool more humanized and the maintenance is simplified.

The button station adopts the console with rotating arm. The operation can be controlled on the panel except for the speed adjusting handle of the table in the front of the bed. The electric box adopts independent electric cabinet with air conditioning refrigeration.

The transverse distance can be directly set arbitrarily by the electric button on the panel. The setting is simple and more efficient. The feed amount can be set directly on the panel.

The machine is equipped with automatic size grinding function, can be fully automatic surface grinding to reach the set size and zero grinding (light knife), the grinding wheel can rise to the fixed point, so as to facilitate the loading and unloading of crops; The power supply of hydraulic motor is automatically turned off immediately, which makes grinding more automatic and greatly reduces labor cost.

The machine has automatic fault alarm function, if the lubricating oil level of the guide rail is too low or the pressure is too low, the machine can automatically stop and alarm.