| Availability: | |

|---|---|

| Quantity: | |

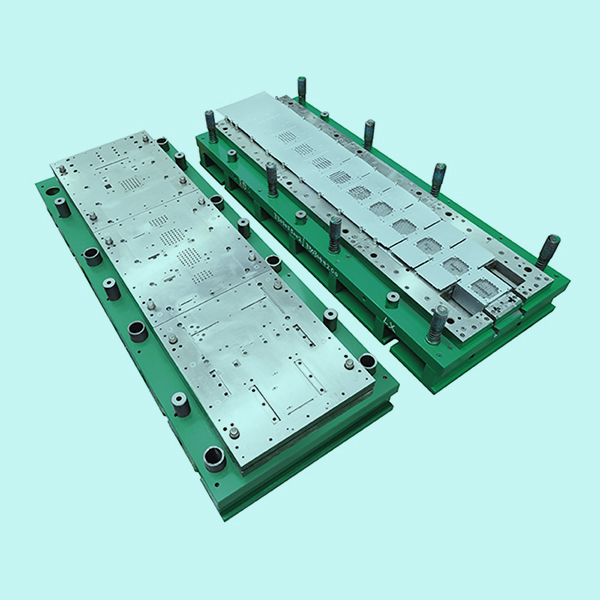

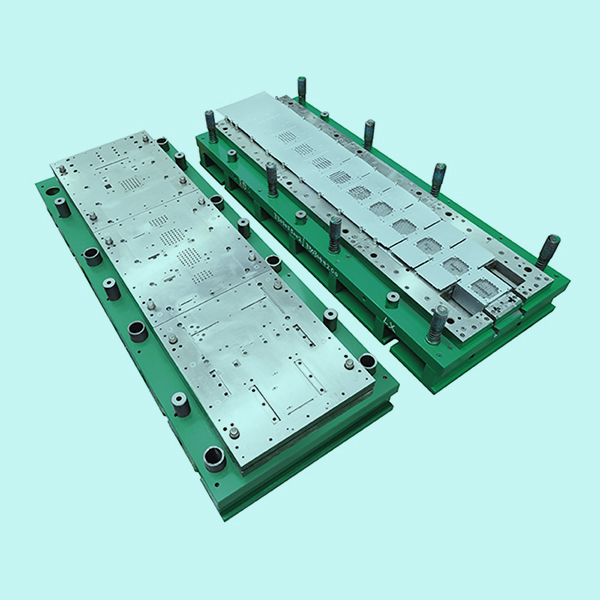

Auto Parts

Machine manufacturer

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

diamond pen | magetic separator | wheel balance stand | DRO |

Description | Unit | M7130A | |

Table size(L*W) | mm | 1000*300 | |

Max.grinding size of workpiece(L*W) | mm | 1000*300*400 | |

Longitudinal travel | mm | 200-1100 | |

Table longitudinal speed | mm/min | 3-27 | |

T-slot of table(No.*width) | mm | 3*18 | |

Distance from spindle center to table surface | mm | 600 | |

Max. loading of table(including magentic chuck) | 470 | ||

Magnetic chuck size | mm | 300*1000 | |

Wheel size(OD*Width*ID) | mm | 400*40*127 | |

Spindle speed(stepless) | r/min | 1440 | |

Worktable speed | m/min | 3-27 | |

Wheelhead transverse moving | Continuous feed rate | m/min | 0.5-4.5 |

Intermittent feed | mm/t | 3-30 | |

Wheel vertical moving | Rapid speed | mm/min | 400 |

Handwheel feed per gra. | Mm/gra. | 0.005 | |

Handwheel feed per rev. | Mm/rev. | 0.645 | |

Spindle motor | KW | 7.5 | |

Hydraulic motor | KW | 3 | |

Cooltant motor | KW | 0.125 | |

Elevating motor | KW | 0.37 | |

Total rated power | KW | 11 | |

Surface roughness | μm | Ra0.63 | |

Gross weight | kg | 3500 | |

Package dimension(L*W*H) | mm | 2840*1710*2130 | |

Description | Unit | M7140 | M7140A*1600 | M7140A*2200 | |||

Table size(L*W) | mm | 1000*400 | 1600*400 | 2200*400 | |||

Max.grinding size of workpiece(L*W) | mm | 1000*400*400 | 1600*400*400 | 2200*400*400 | |||

Longitudinal travel | mm | 200-1100 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 400*1000 | 400*1600 | 400*2200 | |||

Max. loading of table(including magentic chuck) | kg | 630 | 1000 | 1380 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*18 | |||||

Distance from spindle center to table surface | mm | 600 | |||||

Wheel size(OD*Width*ID) | mm | 400*40*127 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.645 | |||||

Spindle motor | KW | 7.5 | |||||

Hydraulic motor | KW | 3 | |||||

Cooltant motor | KW | 0.125 | |||||

Elevating motor | KW | 0.37 | |||||

Total rated power | KW | 11 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 4700 | 6600 | 8000 | |||

Package dimension(L*W*H) | cm | 295*220*233 | 500*220*233 | 680*220*233 | |||

Description | Unit | M7150A | M7150A*1600 | M7150A*2200 | |||

Table size(L*W) | mm | 1000*500 | 1600*500 | 2200*500 | |||

Max.grinding size of workpiece(L*W) | mm | 1000*500*500 | 1600*500*500 | 2200*500*500 | |||

Longitudinal travel | mm | 200-1100 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 500*1000 | 500*1600 | 500*2200 | |||

Max. loading of table(including magentic chuck) | kg | 700 | 1240 | 1410 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 400*40*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 7.5 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Elevating motor | KW | 0.55 | |||||

Total rated power | KW | 12.25 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 5000 | 7100 | 8500 | |||

Package dimension(L*W*H) | cm | 320*228*252 | 520*228*252 | 680*228*252 | |||

Description | Unit | M7170A*1250 | M7170A*1600 | M7170A*2200 | |||

Table size(L*W) | mm | 1250*700 | 1600*700 | 2200*700 | |||

Max.grinding size of workpiece(L*W) | mm | 1250*700*500 | 1600*700*500 | 2200*700*500 | |||

Longitudinal travel | mm | 200-1350 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 700*1250 | 700*1600 | 700*2200 | |||

Max. loading of table(including magentic chuck) | kg | 1100 | 1400 | 1800 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 400*50*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 11 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Transverse motor | KW | 0.55 | |||||

Elevating motor | KW | 0.55 | |||||

Total rated power | KW | 19.75 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 6200 | 6600 | 7200 | |||

Package dimension(L*W*H) | cm | 385*228*255 | 560*228*255 | 680*228*255 | |||

Description | Unit | M7180*1600 | M7180*2200 | M7180*3000 | |||

Table size(L*W) | mm | 1600*800 | 2200*800 | 3000*800 | |||

Max.grinding size of workpiece(L*W) | mm | 1600*800*500 | 2200*800*500 | 3000*800*500 | |||

Longitudinal travel | mm | 200-1700 | 200-2300 | 200-3100 | |||

Magnetic chuck size | mm | 800*1600 | 800*2200 | 800*3000 | |||

Max. loading of table(including magentic chuck) | kg | 1600 | 2000 | 3000 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 450*63*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 15 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Transverse motor | KW | 0.75 | |||||

Elevating motor | KW | 0.75 | |||||

Total rated power | KW | 28.75 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 9500 | 11000 | 13000 | |||

Package dimension(L*W*H) | cm | 490*260*270 | 570*260*270 | 865*260*270 | |||

High strength cast iron foundation

Transverse movement is driven by ball screw, high transmission precision and easy maintenance

Longitudinal moves hydraulically with variable speed

Vertical moves manually or motor drives

The machine is suitable for heavy duty grinding with high grinding efficiency

Forced lubrication guideway, prolong the service life of machine

Machine can be extended into Vertical PLC type or Two axes PLC type,named M71XXD/M71XXPC2

Except M7180 model,all can be either type B(distance from the center line of the spindle to table is 1000mm) or typeC(distance from the center line of the spindle to table is 1400mm),other parameters are same as type A(except the machine height and weight).

Auto Parts

Machine manufacturer

Mould

| Cooltant system | working light | leveling wedges | foundation screw | wheel flange |

| wheel balance arbor | magnetic chuck | standard wheel | operation manual | wheel dressing base |

diamond pen | magetic separator | wheel balance stand | DRO |

Description | Unit | M7130A | |

Table size(L*W) | mm | 1000*300 | |

Max.grinding size of workpiece(L*W) | mm | 1000*300*400 | |

Longitudinal travel | mm | 200-1100 | |

Table longitudinal speed | mm/min | 3-27 | |

T-slot of table(No.*width) | mm | 3*18 | |

Distance from spindle center to table surface | mm | 600 | |

Max. loading of table(including magentic chuck) | 470 | ||

Magnetic chuck size | mm | 300*1000 | |

Wheel size(OD*Width*ID) | mm | 400*40*127 | |

Spindle speed(stepless) | r/min | 1440 | |

Worktable speed | m/min | 3-27 | |

Wheelhead transverse moving | Continuous feed rate | m/min | 0.5-4.5 |

Intermittent feed | mm/t | 3-30 | |

Wheel vertical moving | Rapid speed | mm/min | 400 |

Handwheel feed per gra. | Mm/gra. | 0.005 | |

Handwheel feed per rev. | Mm/rev. | 0.645 | |

Spindle motor | KW | 7.5 | |

Hydraulic motor | KW | 3 | |

Cooltant motor | KW | 0.125 | |

Elevating motor | KW | 0.37 | |

Total rated power | KW | 11 | |

Surface roughness | μm | Ra0.63 | |

Gross weight | kg | 3500 | |

Package dimension(L*W*H) | mm | 2840*1710*2130 | |

Description | Unit | M7140 | M7140A*1600 | M7140A*2200 | |||

Table size(L*W) | mm | 1000*400 | 1600*400 | 2200*400 | |||

Max.grinding size of workpiece(L*W) | mm | 1000*400*400 | 1600*400*400 | 2200*400*400 | |||

Longitudinal travel | mm | 200-1100 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 400*1000 | 400*1600 | 400*2200 | |||

Max. loading of table(including magentic chuck) | kg | 630 | 1000 | 1380 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*18 | |||||

Distance from spindle center to table surface | mm | 600 | |||||

Wheel size(OD*Width*ID) | mm | 400*40*127 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.645 | |||||

Spindle motor | KW | 7.5 | |||||

Hydraulic motor | KW | 3 | |||||

Cooltant motor | KW | 0.125 | |||||

Elevating motor | KW | 0.37 | |||||

Total rated power | KW | 11 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 4700 | 6600 | 8000 | |||

Package dimension(L*W*H) | cm | 295*220*233 | 500*220*233 | 680*220*233 | |||

Description | Unit | M7150A | M7150A*1600 | M7150A*2200 | |||

Table size(L*W) | mm | 1000*500 | 1600*500 | 2200*500 | |||

Max.grinding size of workpiece(L*W) | mm | 1000*500*500 | 1600*500*500 | 2200*500*500 | |||

Longitudinal travel | mm | 200-1100 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 500*1000 | 500*1600 | 500*2200 | |||

Max. loading of table(including magentic chuck) | kg | 700 | 1240 | 1410 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 400*40*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 7.5 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Elevating motor | KW | 0.55 | |||||

Total rated power | KW | 12.25 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 5000 | 7100 | 8500 | |||

Package dimension(L*W*H) | cm | 320*228*252 | 520*228*252 | 680*228*252 | |||

Description | Unit | M7170A*1250 | M7170A*1600 | M7170A*2200 | |||

Table size(L*W) | mm | 1250*700 | 1600*700 | 2200*700 | |||

Max.grinding size of workpiece(L*W) | mm | 1250*700*500 | 1600*700*500 | 2200*700*500 | |||

Longitudinal travel | mm | 200-1350 | 200-1700 | 200-2300 | |||

Magnetic chuck size | mm | 700*1250 | 700*1600 | 700*2200 | |||

Max. loading of table(including magentic chuck) | kg | 1100 | 1400 | 1800 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 400*50*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 11 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Transverse motor | KW | 0.55 | |||||

Elevating motor | KW | 0.55 | |||||

Total rated power | KW | 19.75 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 6200 | 6600 | 7200 | |||

Package dimension(L*W*H) | cm | 385*228*255 | 560*228*255 | 680*228*255 | |||

Description | Unit | M7180*1600 | M7180*2200 | M7180*3000 | |||

Table size(L*W) | mm | 1600*800 | 2200*800 | 3000*800 | |||

Max.grinding size of workpiece(L*W) | mm | 1600*800*500 | 2200*800*500 | 3000*800*500 | |||

Longitudinal travel | mm | 200-1700 | 200-2300 | 200-3100 | |||

Magnetic chuck size | mm | 800*1600 | 800*2200 | 800*3000 | |||

Max. loading of table(including magentic chuck) | kg | 1600 | 2000 | 3000 | |||

Table longitudinal speed | mm/min | 3-27 | |||||

T-slot of table(No.*width) | mm | 3*22 | |||||

Distance from spindle center to table surface | mm | 700 | |||||

Wheel size(OD*Width*ID) | mm | 450*63*203 | |||||

Spindle speed(stepless) | r/min | 1440 | |||||

Worktable speed | m/min | 3-27 | |||||

Wheelhead Transverse moving | Continuous feed rate | m/min | 0.5-4.5 | ||||

Intermittent feed | mm/t | 3-30 | |||||

Handwheel feed per gra. | mm/gra. | 0.02 | |||||

Wheel vertical moving | Rapid speed | mm/min | 400 | ||||

Handwheel feed per gra. | Mm/gra. | 0.005 | |||||

Handwheel feed per rev. | Mm/rev. | 0.515 | |||||

Spindle motor | KW | 15 | |||||

Hydraulic motor | KW | 5.5 | |||||

Cooltant motor | KW | 0.125 | |||||

Transverse motor | KW | 0.75 | |||||

Elevating motor | KW | 0.75 | |||||

Total rated power | KW | 28.75 | |||||

Surface roughness | μm | Ra0.63 | |||||

Gross weight | kg | 9500 | 11000 | 13000 | |||

Package dimension(L*W*H) | cm | 490*260*270 | 570*260*270 | 865*260*270 | |||

High strength cast iron foundation

Transverse movement is driven by ball screw, high transmission precision and easy maintenance

Longitudinal moves hydraulically with variable speed

Vertical moves manually or motor drives

The machine is suitable for heavy duty grinding with high grinding efficiency

Forced lubrication guideway, prolong the service life of machine

Machine can be extended into Vertical PLC type or Two axes PLC type,named M71XXD/M71XXPC2

Except M7180 model,all can be either type B(distance from the center line of the spindle to table is 1000mm) or typeC(distance from the center line of the spindle to table is 1400mm),other parameters are same as type A(except the machine height and weight).